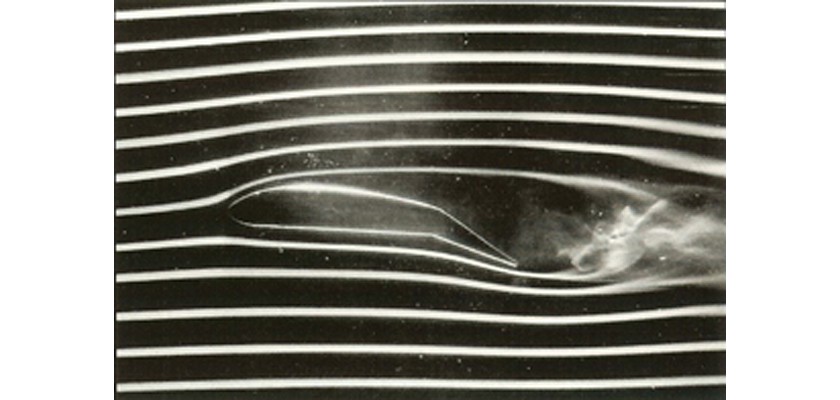

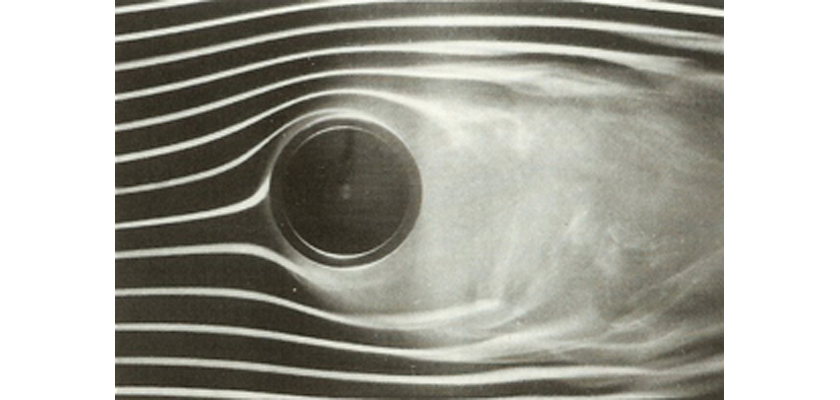

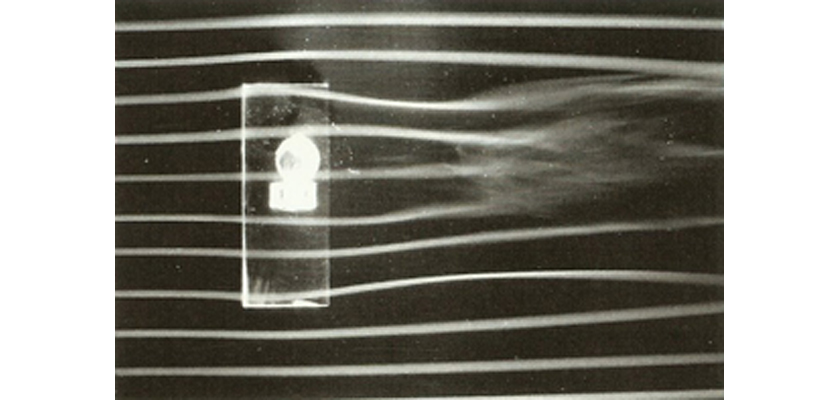

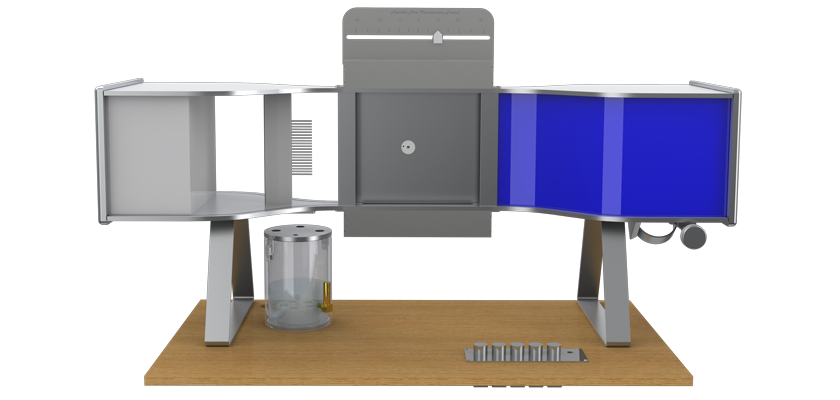

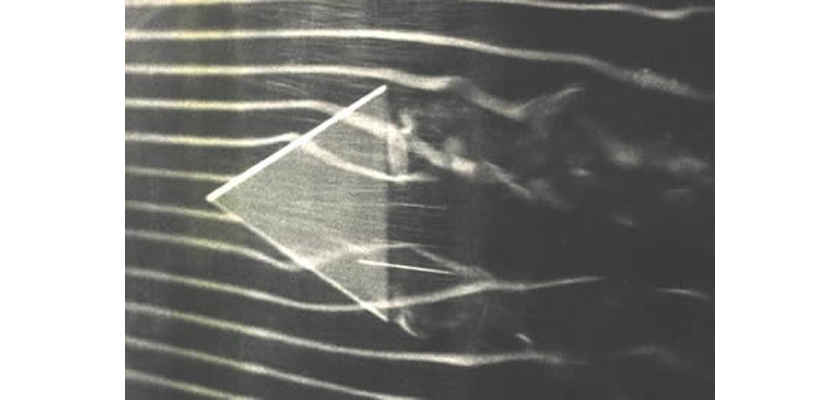

The shape of an object moving through a fluid has a major influence on the way the fluid reacts.

Using the AEROLAB Flow Visualization Tunnel, students can see firsthand the flow of air over objects such as airfoils, cylinders and other aerodynamic shapes.

While the AEROLAB Flow Visualization Tunnel is great for group demonstrations, it’s also intended for hands-on student experimentation. Students can change pitch angles, deflect flaps, rotate circular cylinders and apply vacuum and/or blowing to improve aerodynamic performance. Hands-on activities motivate learners because the effects of their adjustments are immediate and obvious.

Overall Dimensions

Wind tunnel

- Length: 53 inches (1.35m)

- Height: 28.5 inches (72cm)

- Width: 17 inches (43cm)

Cabinet

- Height: 37 inches (94cm)

- Width: 45.5 inches (1.16m)

- Depth: 24 inches (61cm)

- Power requirements: 115 VAC, 60 Hz, minimum 15 Amp circuit, international use requires a transformer

Further Reading

Flow Visualization tunnels, in particular, require exceptionally smooth, steady airflow. This quality of airflow is aerodynamically termed “laminar” flow. Laminar flow contains no eddies or other types of turbulence. Turbulence is undesirable because it diffuses the injected water vapor lines, causing them to lose definition and appear fuzzy.

In general, laminar flow is not easy to generate and is difficult to maintain. Two factors promote laminar flow: a carefully designed inlet bell mouth (known as the “contraction”) and an effective “honeycomb” flow straightener.

The AEROLAB Flow Visualization Tunnel design includes a large-area-ratio (inlet to outlet) contraction and engineered aluminum honeycomb. The honeycomb provides approximately 7700 hexagonal channels, 7 inches in length and 1/8 inch across flats (Aspect Ratio 56). Honeycomb is also employed at the exit of the model area to ensure laminar flow.

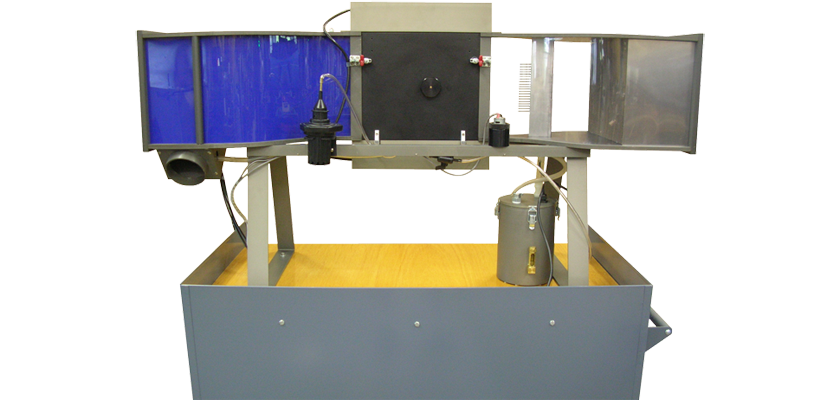

Vaporized water (created by an ultrasonic atomizer) is introduced in streaklines spaced 0.25 inches (6.35mm) apart through a special rake. The rake is located near the exit of the contraction.

The ultrasonic atomizer is housed in an enclosure directly below the smoke rake. During prolonged use, water vapor condenses in the vapor line. To remove the water droplets and restore vapor flow, the control panel has a purge button.

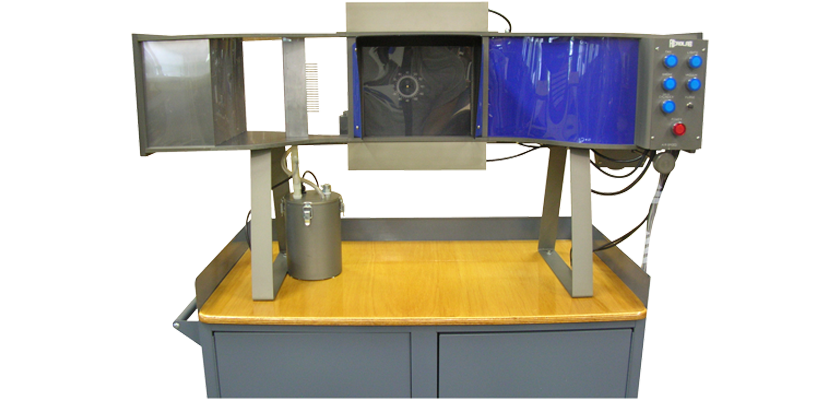

Airflow is generated by a centrifugal blower downstream of the test section. Airspeed is infinitely controllable through a knob on the main control panel. The knob is attached to a flap which throttles the flow to the blower.

The flow visualization tunnel is fabricated with an aluminum frame consisting of top and bottom plates. Suitably cross-braced, it stands on aluminum legs. The top and bottom plates have machine-milled grooves that retain the acrylic sides.

One side of the converging section, the contraction, and the test section are enclosed with a single piece of clear acrylic. This construction enhances the appearance and makes visible the entire vapor rake and streamline flow pattern. The side walls downstream of the test section are formed of opaque blue acrylic to harmonize with the anodized aluminum.

The rear wall of the test section is finished in non-reflective black to enhance viewing and photography. A removable visor is added to diminish the effect of exterior light.

Only airspeed and model position are controlled by the operator. The atomizer begins to function virtually immediately, so warm-up time is not required.

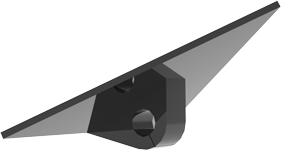

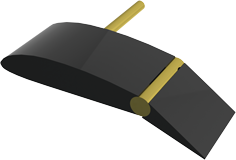

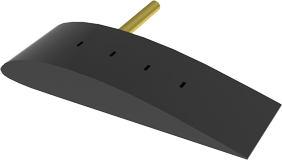

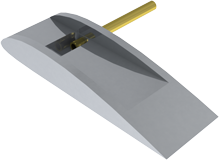

Models are mounted by opening the hinged back panel and inserting the model stem through the angle-of-attack mechanism.

Air under positive or negative pressure can be piped from the compressor-vacuum pump to models and controlled with a small hand-operated valve. The rotating cylinder model rotates at a fixed speed. Fluorescent lights are mounted both above and below the test section to illuminate the model and the streak lines.

Venturi

The Venturi model serves to demonstrate the effect of a converging duct on moving air. Observe the streaklines as they pass through the model. Change the pitch angle of the model and observe the streaklines.

Circular Cylinder (Spin Model)

The Circular Cylinder serves to demonstrate the Magnus Effect. Operate the tunnel with and without the cylinder spinning. Note the direction of the spin and the effect on the streaklines.

Type

- Specialty Tunnels/Equipment

Overall Dimensions

Wind tunnel

- Length: 53 inches (1.35m)

- Height: 28.5 inches (72cm)

- Width: 17 inches (43cm)

Cabinet

- Height: 37 inches (94cm)

- Width: 45.5 inches (1.16m)

- Depth: 24 inches (61cm)

- Power requirements: 115 VAC, 60 Hz, minimum 15 Amp circuit, international use requires a transformer