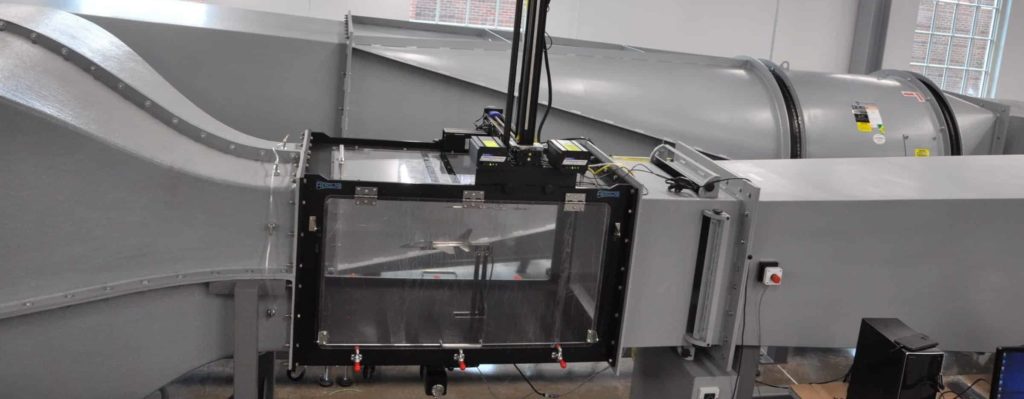

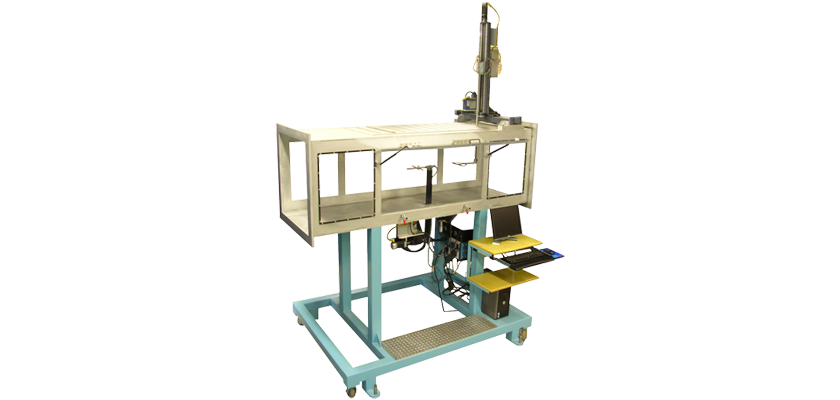

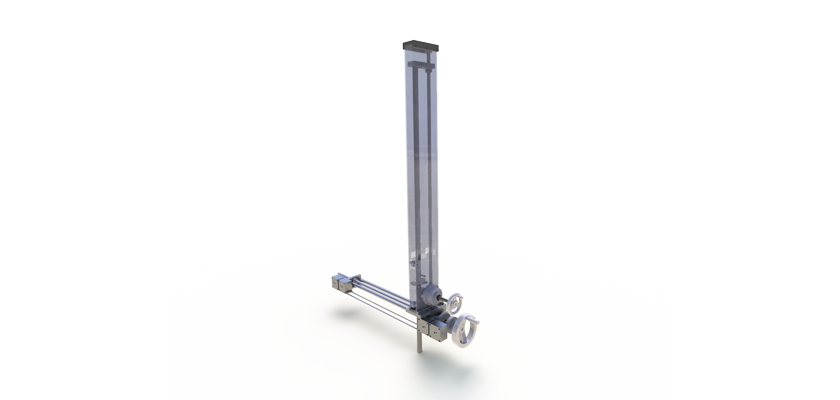

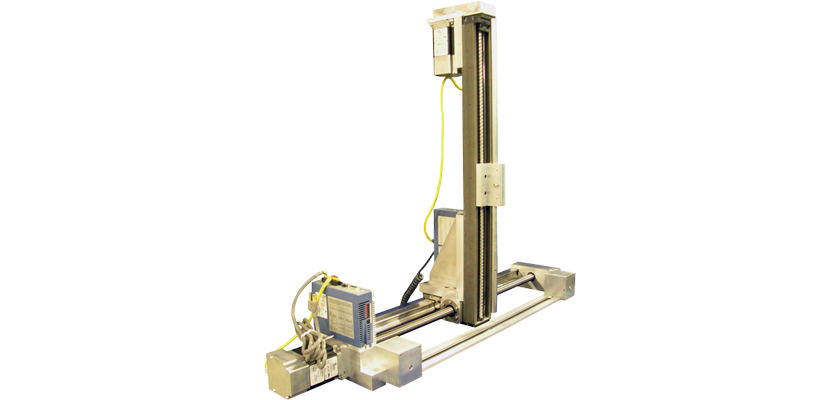

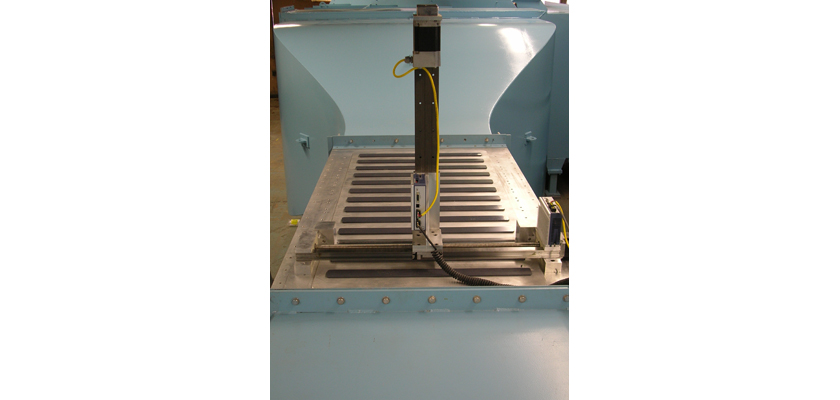

AEROLAB designs and manufactures test section traverse systems for any subsonic wind tunnel.

Typically, traversing systems are used to study the airflow behind a test model (a pressure probe is mounted to the traversing arm).

AEROLAB systems are accurate, simple and easy-to-use. Motion in the Y / Z-plane (perpendicular to the airflow) is controlled by high-quality stepper motors while X-axis location (parallel to the airflow) is adjusted manually in discrete steps.

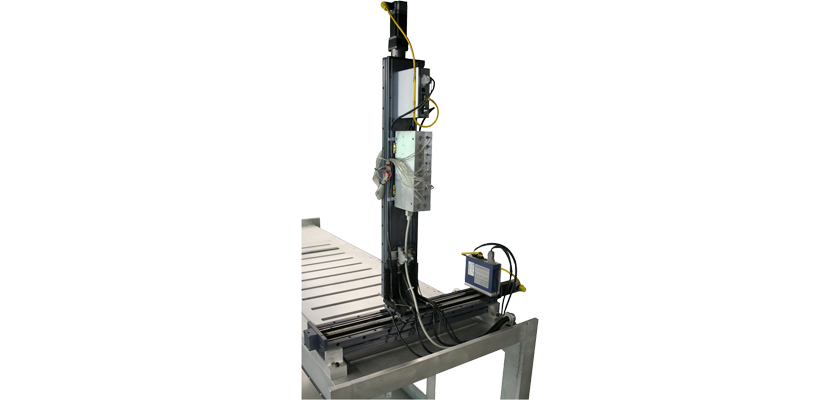

Installation to an existing test section requires modification of the ceiling plate.

Performance Specifications

- Position accuracy – customer defined

- Sweep area – based on each unique test section and application

Detailed Description

Designed for each unique test section and application, AEROLAB traverse systems are built of high-quality materials and components.

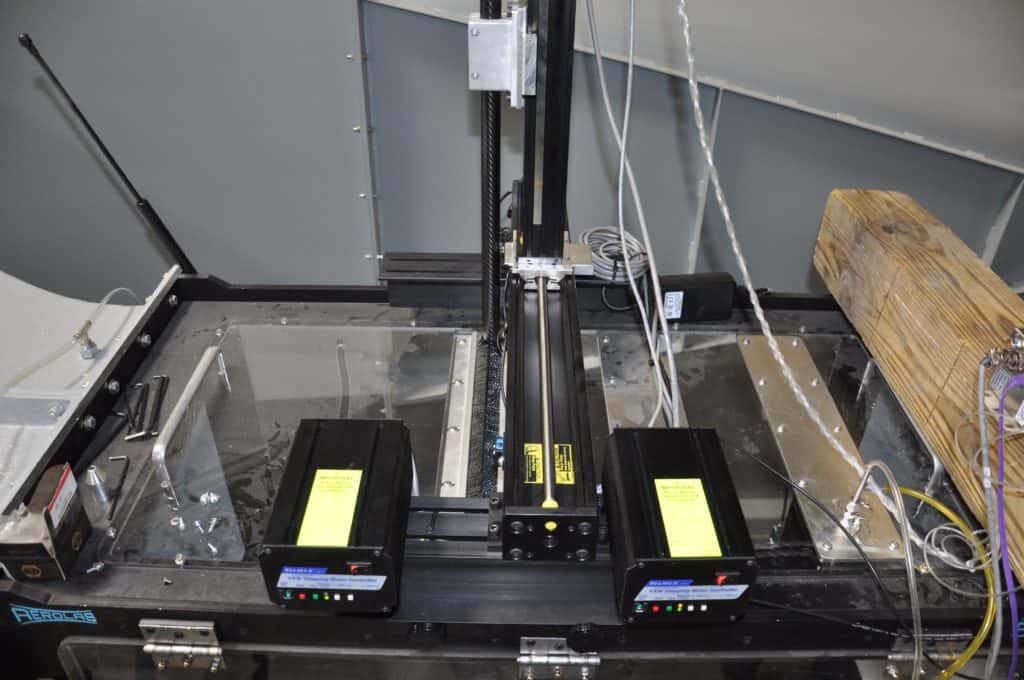

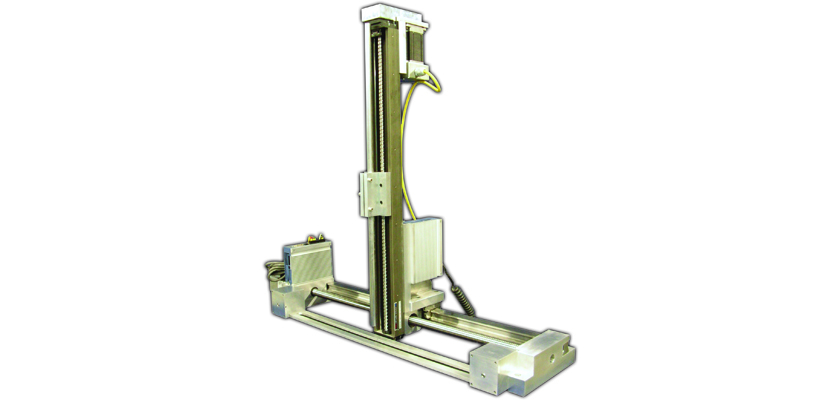

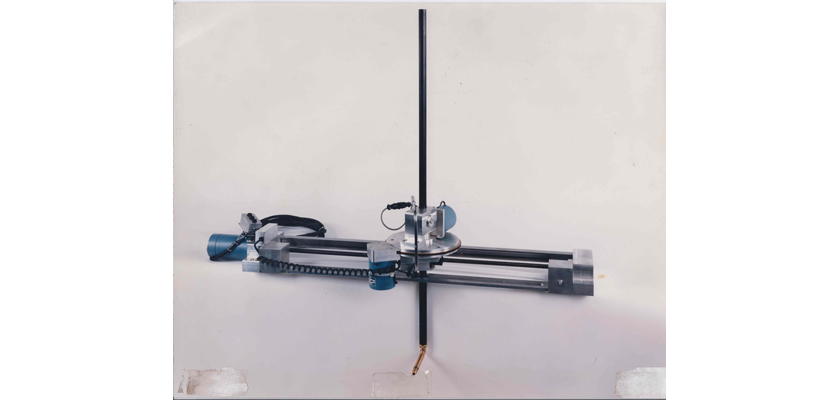

Movement of the test probe is carried out on two precision actuator rails. The rails employ high-quality stepper motors to drive the probe holder with a high degree of resolution, repeatability and virtually no backlash.

To allow for stream-wise position changes (along the X-axis, parallel to the airstream), AEROLAB slots the test section ceiling. Manually, the system is relocated from slot to slot. When not in use, empty slots are sealed with machined Acrylic plugs. The plugs also smooth the ceiling – filling the slots without protruding into the airstream or producing shallow recesses.

AEROLAB designers have come up with a brilliant solution to seal the slot occupied by the traverse arm. Spring-loaded, a thin metal plate follows the traverse arm. The plate does not affect the movement of the traverse arm yet prevents entrainment of outside air.

Optional Features

Related Products

- Open Circuit Wind Tunnel

- Closed Circuit Wind Tunnel

- Complete Test Section Fabrication

Type

- Specialty Tunnels/Equipment

Performance Specifications

- Position accuracy - customer defined

- Sweep area - based on each unique test section and application

Questionnaire