Custom Closed Circuit Wind Tunnel System for Khalifa University of Science

Khalifa University of Science recently acquired a custom wind tunnel to enhance its aerodynamic research capabilities. The project involved designing, fabricating, delivering, and installing a closed circuit wind tunnel system that would meet the university’s specific requirements for flow quality and operational efficiency.

The university needed a wind tunnel with two distinct test sections—one for low-speed and another for high-speed testing—while maintaining stringent standards for turbulence and pressure variation. The challenge was to design a system that would achieve these performance metrics within the spatial and budgetary constraints provided.

The proposed wind tunnel system included two test sections arranged in tandem:

Low-Speed Test Section

Dimensions: 2.5m x 2.1m x 4m

Contraction Ratio: 2.286:1 from the primary settling chamber

Maximum Speed: 16 m/s

High-Speed Test Section:

Dimensions: 1.2m x 1m x 6m

Contraction Ratio: 10:1 from the primary settling chamber and 4.375:1 from the low-speed section

Maximum Speed: 70 m/s

The design focused on minimizing turbulence downstream of the stator, with turbulence intensity reduced to less than 0.01% in both streamwise and crossflow directions. The temperature within the test sections was carefully controlled to maintain uniform conditions throughout the testing process.

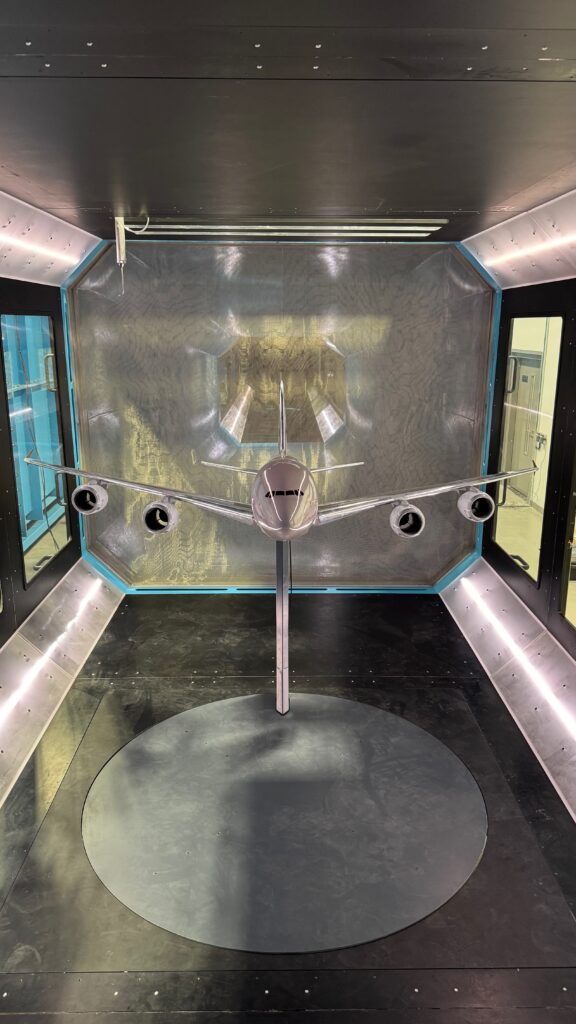

The tunnel is also equipped with a full array of instrumentation and equipment from a internal sting balance, external external balance, traverse system, and wind tunnel models

The custom wind tunnel delivered to Khalifa University met all performance and operational goals. The system provided a reliable and precise environment for aerodynamic testing, with the required flow quality and operational control achieved.

The project demonstrates the effectiveness of tailored design and meticulous engineering in achieving high standards for aerodynamic research facilities.