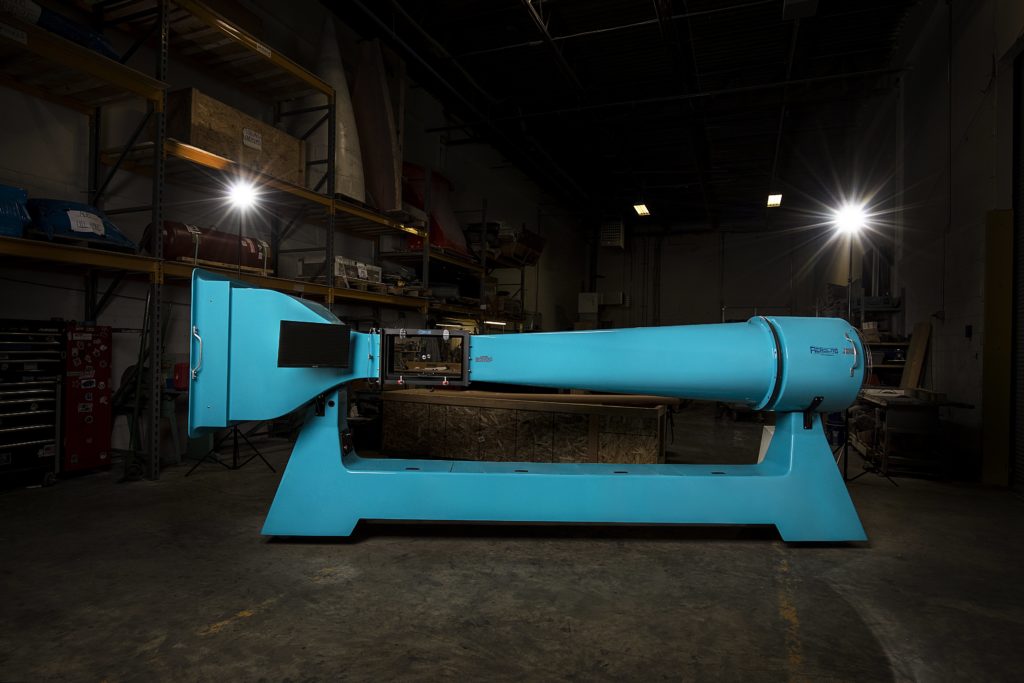

The AEROLAB Educational Wind Tunnel (EWT) System is a powerful tool for educators and researchers alike.

With many optional features available, the budget-conscious user can start with a basic system and upgrade as needs change or funding becomes available.

The Complete EWT System is an easy-to-use, all-in-one fluids / aerodynamics laboratory. Optional features include instrumentation, data acquisition, models and probes. Contact AEROLAB and build a system today.

Perfectly scaled for high school or university use, the basic EWT system is also popular with small technical businesses needing an accurate, reliable testing device.

Performance Specifications

- Airspeed Range – 10 mph (4.5 m/s) to 145+ mph (65 + m/s)

- Turbulence Level – less than 0.2%

- Reynolds Number (per foot) – 1.4 x 10^6 /foot

Detailed Description

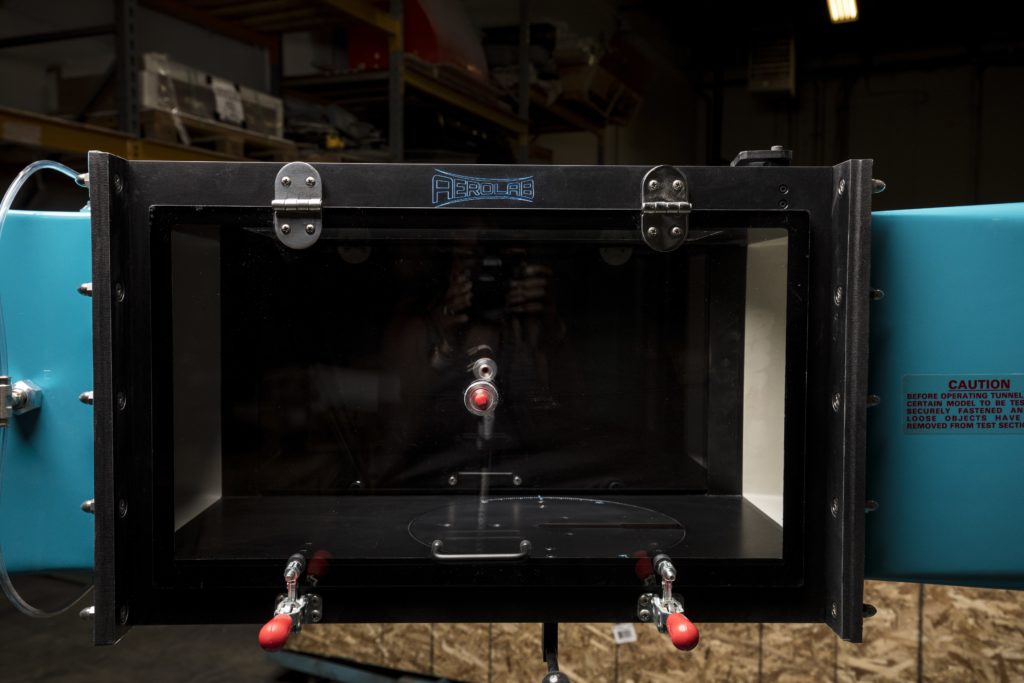

- Test Section Dimensions – 12”x12”x24” (30.5cm x 30.5cm x 61cm)

- Length – 15 feet (4.6m)

- Width – 42 inches (1.1m)

- Height – 6 feet (1.8m)

- Weight – approximately 600 pounds (272 kg)

- Power – 10 hp (7.5 KW) electric motor

- Mobility – Four (4) industrial-grade steel casters with polyurethane wheels

- Fiberglass Construction – Accurately-formed, rugged, and strong

- Honeycomb Flow Straightener – Expanded aluminum, 4-inch deep hexagonal cells

- Turbulence-reducing Screens – Two (2) 20×20 (mesh) stainless steel screens

- Contraction Contour – 9.5:1 propietary contraction

- Static Pressure Ring – Non-invasive access to test section static pressure used for airspeed indication

- Test Section – Anodized aluminum structure with integrated yaw table

- Visibility – Two (2) top-hinged Acrylic side doors and one (1) top window

- Diffuser – 6-deg included divergence angle with an expansion ratio of 1:3

- Motor Control – Variable Frequency Drive (VFD), configurable to all international Voltages

- Noise Attenuator – Integrated double-walled construction

Data Acquisition, Display and Control (DAC) System

- National Instruments hardware and LabVIEW software (no license necessary)

- Capable of monitoring: Force/Moment Balance output, pressures, model angle of attack, and temperature (additional hardware required)

- Capable of setting and maintaining wind tunnel airspeed (dynamic pressure) regardless of model orientation

- Dell desktop computer with required peripherals included

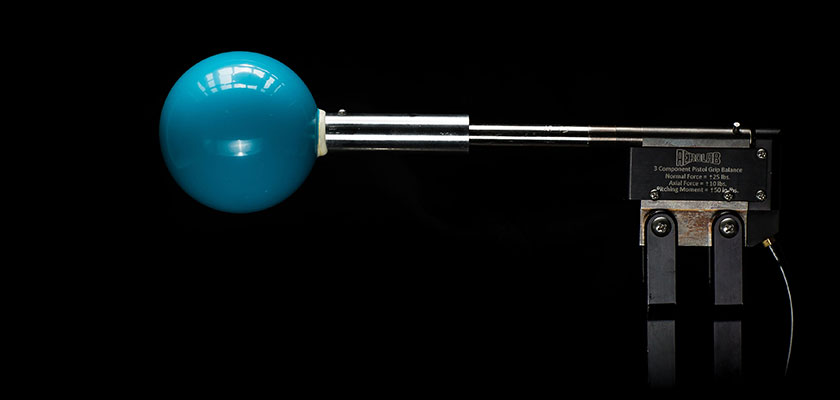

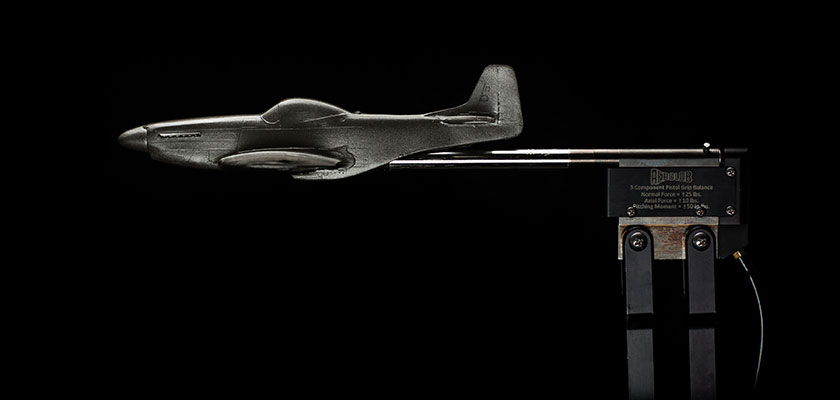

3-Component Force/Moment Sting Balance

- Simultaneously measure Normal Force, Axial Force, and Pitching Moment

- Quickly reconfigurable to measure Side Force, Axial Force, and Yawing Moment

- 3/8-inch outside diameter sting mount

- Adaptable to alternate model positioning systems

- 1st-order Factory calibration (supplied with Balance-specific calibration bar)

Brochure

See the Educational Wind Tunnel (EWT) brochure.

Type

- Low Speed

- Subsonic

Performance Specifications

- Airspeed Range - 10 mph (4.5 m/s) to 145+ mph (65 + m/s)

- Turbulence Level - less than 0.2%

- Reynolds Number (per foot) - 1.4 x 10^6 /foot

Questionnaire

The following questionnaire is intended to streamline the purchase of your new AEROLAB Educational Wind Tunnel (EWT) Upgrade. Please answer the questions as carefully and thoroughly as possible and maintain a common units system (ex. Inches, feet, meters, pounds, etc.). AEROLAB is not responsible for the accuracy of the information it is provided. Double-check all measurements and include additional information and/or photographs as needed to facilitate understanding.